Styrene butadiene rubber manufacturing process pdf

Styrene butadiene rubber manufacturing process pdf

butadiene rubber, L-SBR means styrene-butadiene rubber produced by polymerization in solution, H-NBR is hydrogenated acrylonitrile-butadiene rubber, CIIR is chlorinated isobutene-isoprene rubber etc. Natural rubber is marked with

choice of the particular rubber, the compound composition, the production process and the shape and design of the product. Depending on the type and amount of

Production of styrene–butadiene rubber and polybutadiene rubber accounts for about 54% of global butadiene demand, with tire production being the single most important end use of butadiene synthetic rubbers. Other major butadiene derivatives are acrylonitrile–butadiene–styrene (ABS) and styrene butadiene latex (about 24% of demand combined).

materially injured by reason of imports of certain emulsion styrene‐butadiene rubber from Brazil, Korea, Mexico, and Poland, provided for in subheading 4002.19.00 of the Harmonized Tariff Schedule of the United States, that are alleged to be sold in the United States at less than

The XSBR latexes (styrene-butadiene carboxylated latexes, also known as “CBX”) process is based on an emulsion polymerization reaction in a semibatch (“seed polymerization”) reactors.

4.12 Manufacture of Rubber Products. 4.12.1 General Process Description1. Many of the rubber manufacturing facilities in the United States produce pneumatic tires for automobile, trucks, airplanes and farm machinery. However, many rubber manufacturing facilities produce other engineered rubber products. The processes involved in these industries are very similar. Differences basically consist

A process for the preparation of acrylonitrile-butadiene-styrene resins wherein styrene and acrylonitrile are copolymerized in the presence of a soluble butadiene reinforcing rubber, the butadiene rubber being dissolved in a mixture of acrylonitrile and styrene, initiating polymerization of the styrene and acrylonitrile thereby causing the rubber under the influence of agitation to separate in

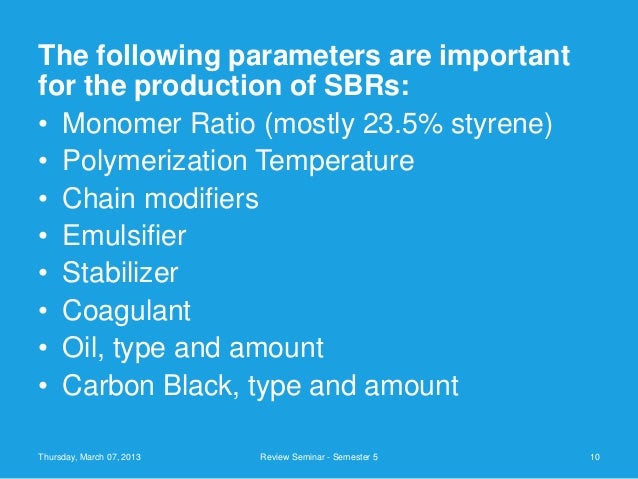

SBR is produced by the copolymerisation of butadiene with styrene in the approximate proportion of 3:1 by weight. In the emulsion process, producing general purpose grades, the feedstocks are suspended in a large proportion of water in the presence of an initiator or a catalyst and a stabiliser.

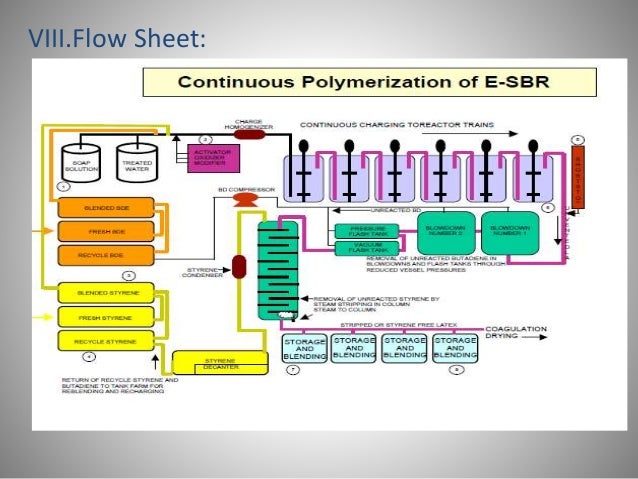

Production Process Overview Introduction Production Process Overview –Emulsion Polymerization of SBR –Solution Polymerization of SBR and PBR Production Economics Emulsion SBR & Solution Polymerization of SBR and PBR Production Economics Tables World Trade Introduction Butyl Rubber Trade Grids Nitrile Rubber Trade Grids Polybutadiene Rubber Trade Grids Emulsion Styrene Butadiene Rubber

Polybutadiene (BR) is the second largest volume synthetic rubber produced, next to styrene-butadiene rubber (SBR). Consumption was about 1,953,000 metric tons worldwide in 1999. Polybutadiene also has a major application as an impact modifier for polystyrene and acrylonitrile-butadiene-styrene resin

RUBBER PROCESSING TECHNOLOGY 1. Rubber Processing and Shaping 2. Manufacture of Tire and other Rubber Products 3. Design Consideration 2 Introduction • Similar to the processing of plastics • But the rubber industry is quite different from the plastics industry • Dominated by one product: tires • Technological breakthrough – Vulcanization (cross-linking) to transform weak natural

Styrene-Butadiene Rubber by Solution Process Production Costs at Difference Production Levels . . Styrene-Butadiene Rubber by Alfin Process Using High

Industry Insights. The global solution styrene butadiene rubber (S-SBR) market size was estimated at USD 2.51 billion in 2016. The increasing utilization of solution styrene butadiene rubber in tire and footwear applications is expected to drive demand over the forecast period.

Styrene Butadiene Polymer Organic Chemistry Organic

Butadiene Dow Chemical Company

exothermic process, the reaction can become self accelerating. Styrene homo polymerization can occur either by free-radical or ionic reactions. The resultant polymer, polystyrene, is a clear, crystalline-type compound.6-s ABS polymers (Fig. 2) can be produced by two general methods, each of which generates a different type of plastic. Type A ABS polymers are produced by a mechan ical

Also, the styrene-butadiene rubber ever, the condition of the whether it is sticky and dense or whether it is relatively dry and fiuffy, influences the 3,350,371 Patented Oct. 31, 1967 See operators in producing styrene-but-adiene rubber have chosen to operate at reduced rates rather than run the risk of too frequent shutdowns.

Process overview Styrene-butadiene rubber (SBR) is the most commonly produced synthetic rubber and it is mostly used for the manufacture of tires and to substitute natural rubbers. There are two different process types utilized for SBR production: emulsion polymerization and solution polymerization. In emulsion polymerization, the monomers polymerize in the presence of an …

STYRENE C. 8. H. 8. Typical end products. Polystyrene, ABS plastics, styrene butadiene, rubber. Chemical curve: Ethylbenzende in Styrene R.I. per Conc% b.w.

Styrene, the simplest and most important member of a series of aromatic monomers, is produced in large quantities for polymerization. Its versatility has resulted in the manufacture of plastics, including polystyrene, ABS, SAN, styrene–butadiene latex, SBR, and unsaturated polyester resins. Polystyrene accounts for 65% of total styrene demand. Rapid growth in styrene production has been seen

Styrene-butadiene rubber is currently the largest volume synthetic rubber, which is produced by the copolymerization of styrene and butadiene by either the emulsion or solution process. Although the emulsion process is clearly the current capacity leader, the solution process has better future potential due to versatility and flexibility in imparting desired polymer structure. The current

Evaluation the Effects of Styrene Butadiene Rubber Addition as a New Soil Stabilizer on Geotechnical Properties.pdf Kirk-Othmer Encyclopedia of Chemical Technology V5 4th Edition.pdf Influence of Silane Coupling Agent on Pyrolysis Pattern Of

Confidential. © 2017 IHS Markit™. All rights reserved 4 Polystyrene Expandable polystyrene ABS Styrene Butadiene Latex Styrene Butadiene Rubber

%20MARKET-min.png)

copolymerization of styrene and butadiene. Polybutadiene is formed from the polymerization process of 1,3-butadiene Polybutadiene is formed from the polymerization process of 1,3-butadiene monomer.

Emulsion styrene butadiene rubber (SBR) market is the largest segment in the global SBR market owing to the low-cost of production. Furthermore, shift in demand from the end users for high

Typical monomers used for production feed material include butadiene, styrene, isoprene, chloroprene, acrylonitrile, ethylene or propylene. These monomers are then polymerized using catalyst and process steam to form chains of polymers which results in rubber intermediaries. These substances are then processed to their final rubber products by vulcanization. In integrated plants, naphtha or

APAC styrene butadiene rubber market volume by application, 2014 – 2025 (Kilo Tons) The key raw materials for manufacturing SBR include styrene and butadiene. The major suppliers of these raw materials are Sinopec, Sibur, and China National Petroleum Corporation.

Process Analytics Production of Synthetic Rubber Process Gas Chromatograph MAXUM edition II controls and optimizes Butyl Rubber production Rubber Rubber is a collective term for macromolecular substances of natural (natural rubber, NR) or synthetic (synthetic rubber, SR) origin. Natural rubber was already used by the Mayas but was recognized as technical material first in 1851 …

In addition, the growing demand for Styrene-butadiene rubber (SBR) in the industry for the manufacturing process is expected to positively drive the market over the forecast period. The report reviews the size and performance of the market research industry and explores how the research market continues to expand, using data collected by national research associations, leading companies

PDF A cohort of 12,110 male workers employed 1 or more years in eight styrene-butadiene polymer (SBR) manufacturing plants in the United States and Canada has been followed for mortality over a

Production of SBR-Latex & SBR-Rubber. Seite 2 Two Types ofStyrene Butadiene Rubber (SBR) 2. SBR-Rubber •Synonyms: SBR, SBR-Elastomer, SB-Elastomer, SB-Rubber •Solid material, properties similar to natural rubber, crosslinkable •Main applications: tires, tubes, mechanical rubber goods, shoe sole •60% of globally produced SBR 1. SBR-Latex •Synonyms: SB-Latex, SBR liquid •Liquid

About SBR. SBR is a synthetic rubber formed by the copolymerization of styrene and butadiene in the ratio of 3:1 by weight. SBR is manufactured through two different processes: emulsion and solution, to form emulsion-SBR and solution-SBR, respectively.

Styrene is mainly used as a raw material for the production of polystyrene and styrene-butadiene rubber (SBR). Because of these two important products, the production of styrene-based polymers has become the world’s third largest polymer production. First and second ranks are obtained by the production of ethylene and

Styrene, butadiene, and carboxylic acid are the primary monomers, and surfactant and other additives including an initiator are charged to create the desirable molecular weight, particle size and gel content.

The chemical behavior of styrene-butadiene rubber (SBR) and of the SBR/TiO2 and photodegraded SBR/TiO2 nanocomposites was investigated through nuclear …

Difference Between Styrene and Polystyrene Styrene vs

The industrial production of two styrene−butadiene rubber (SBR) grades is optimized by means of a representative mathematical model. The emulsion process involves a train of seven continuously stirred-tank reactors.

Major uses of 1,3-butadiene include the manufacture of styrene-butadiene rubber, polybutadiene rubber, and adiponitrile. Full text Get a printable copy (PDF file) of the complete article (320K), or click on a page image below to browse page by page.

sbr (styrene-butadiene-rubber) tyrene-butadiene rubbers (SBR) are copolymers used two monomer styrene and butadiene. utadiene structural units can be as cis-1.4, trans-1.4 or 1.2 (vinyl) units.

Butadiene is used primarily as a monomer for manufacturing synthetic rubber and plastics. Smaller amounts are used as a chemical Smaller amounts are used as a chemical intermediate for producing other chemicals. 2 For further details, see Product Uses.

Solution polymerized styrene-butadiene rubber is the unrivalled raw material for highly specified tyre components used in the fabrication of high performance tyres, where the lowest fuel consumption and the highest durability are required. – canadian child passport renewal application form abroad Styrene Butadiene Rubber (SBR) Production and Manufacturing Process SBR is produced by the copolymerisation of butadiene with styrene in the approximate proportion of 3:1 by weight. producing general purpose grades. such as Asahi Chemical.

Extracting 1,3-Butadiene from a C4 Stream. The organic compound 1,3-butadiene is a petrochemical commodity used as a raw material for the production of rubbers and plastics, such as polybutadiene rubber (PR), styrene butadiene rubber (SBR), and acrylonitrile butadiene styrene (ABS).

1. Introduction. Styrene–butadiene rubber (SBR) is a synthetic elastomer with wide range of industrial applications. Due to its excellent abrasion resistance and stability it is extensively used as a …

production of styrene/butadiene rubber (SBR) sati sfied this requirement. Today, millions of Today, millions of tons of synthetic latexes are produced by th e emulsion polymerization process for use in

Styrene Butadiene Latex Market, By Region In 2016, Asia Pacific held a major share in the global styrene butadiene latex market size, in terms revenue and volume. China was the largest producer and consumer for paper in 2016, which eventually makes it an important contributor in production of global styrene butadiene latex industry.

second place worldwide in terms of volume of production, behind only natural rubber. Thus, according to McGraw and Petrovic [1], the capacities for the production of different types of rubber based on styrene and butadiene in 2013 amounted to over 6 million t. The main consumer of these products is the tyre industry. The constant increase in requirements concerning the safety of motor

Rubber Processing and Profiting Compounding, Mixing, Vulcanization, Extrusion, Materials, Principles Rubber Products, Natural Rubber Processing, Rubber Reclaiming. www.entrepreneurindia.co The production of rubber and rubber products is a large and diverse industry. The rubber product manufacturing industry is basically divided into two major sectors: tyre and non-tyre. The tyre sector

Styrene butadiene rubber is most widely used elastomer in the world.SBR is used forboth tire and non-tire application Styrene butadiene rubber known as Buna-S was first prepared by I.G. Farbenindustrie in …

230 STYRENE–BUTADIENE COPOLYMERS Vol. 4 Houdry process or the oxidative dehydrogenation of n-butenes. Finally in some Asian countries, butadiene is also produced from ethanol.

The next step is obvious: just add more styrene monomer, and get a styrene-butadiene-styrene triblock copolymer. Easy as pie. Funny thing, though. Although butadiene monomer will add to the anion at the end of a polystyrene chain, styrene monomer won’t add to the anion at the end of a living polybutadiene chain. This is most inconvenient. To get around this, we do a little trick: we’re going

From this point in the manufacturing process, latex is processed continuously. The latex is pumped from the blend tanks to coagulation vessels, where dilute sulfuric acid (H2SO4 of pH 4 to 4.5) and sodium chloride solution are added. The acid and brine mixture causes the emulsion to break, releasing the styrene-butadiene copolymer as crumb product. The coagulation vessels are open to the

butadiene-styrene (ABS), both representing approximately 9% of styrene use, and styrene-butadiene rubber (SBR), representing approximately 6% of styrene use. SBR is …

Industry Insights. In 2016, the global solution styrene butadiene rubber (S-SBR) market size was valued at USD 2.51 billion. The demand for S-SBR in footwear and tire applications is increasing owing to its high synthetic flexibility is expected to drive market growth.

As styrene butadiene rubber is one of the key components of synthetic rubber, trends in production and supply of styrene butadiene rubber. Considering the large amount of SBR that is being consumed in the manufacture of tires and tire products, demand is very much dependent on the automotive industry and tire sectors as a whole. As styrene butadiene rubber products are used in almost all

styrene-butadiene rubber (SBR), polybutadiene rubber (PBR), polychloroprene (Neoprene) and nitrile rubber (NR). However, the major use of butadiene is in the production of tires. Butadiene is consumed in the manufacture of polymers, latexes, and plastics. Rubbers and latexes made from butadiene are used to make the following goods and materials: SBR and PBR are used to produce …

Polymer SBR is described as styrene-butadiene or styrene-butadiene rubber, therefore named as polymer SBR. It is part of the families of synthetic rubbers existing out of styrene and butadiene. Polymer SBR is a copolymer of styrene and butadiene and has characteristics like natural rubber.

Antifoams for the Production of SBR-Latex and SBR-Rubber

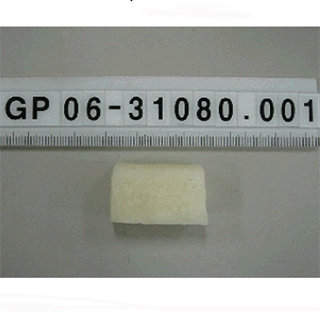

Abstract – Styrene-butadiene rubber (SBR) has large applications in the shoe industry, especially as expanded sheets used to produce insoles and inner soles. According to TG analysis, the rubber …

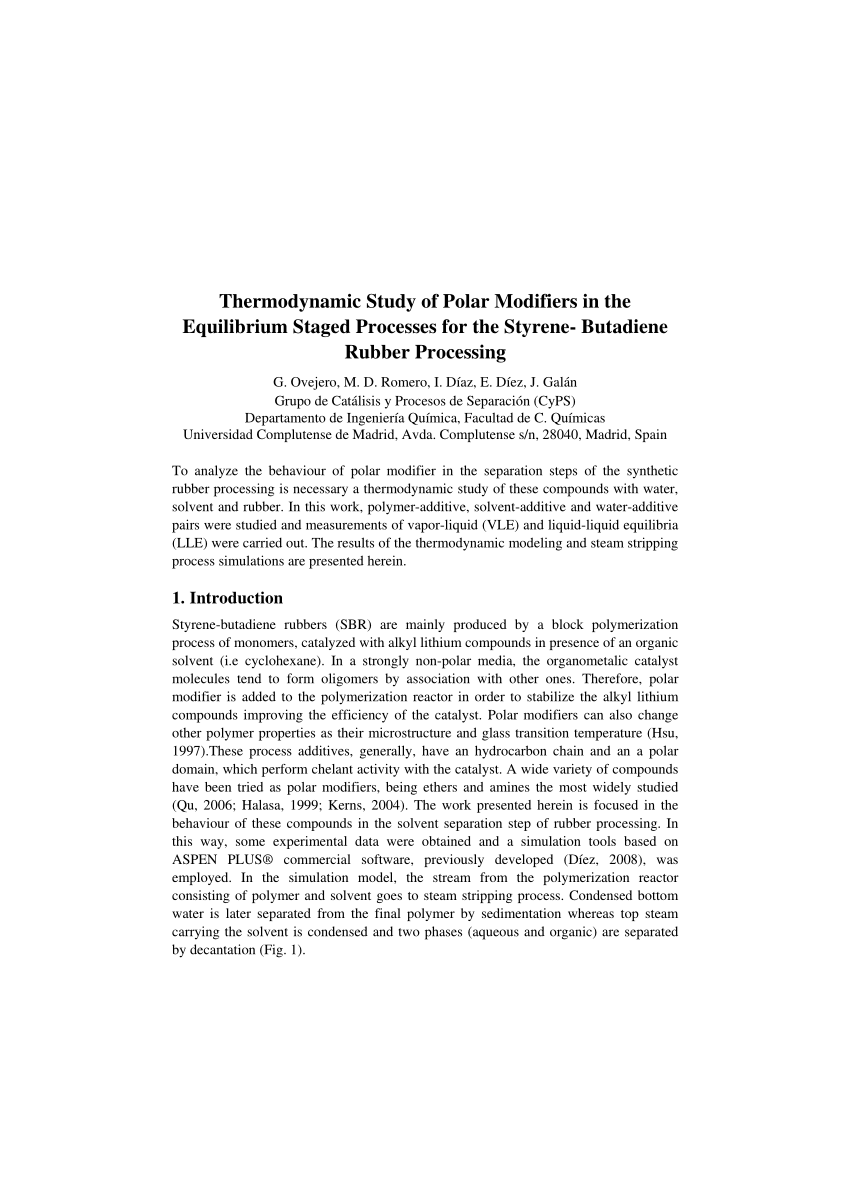

The process The following paragraphs describe a cold emulsion-polymerization process for SBR production from butadiene and styrene. SBR grades generated in this type of process are usually referred to as emulsion SBR (eSBR). Figure 1 presents a simplified flow diagram of the process, showing the main pieces of equipment. Figure 1. This figure shows a diagram of SBR production from styrene …

The rubber market is categorized as natural rubber (NR), which is obtained from rubber trees, and synthetic rubber, which is manufactured with petroleum-based feedstocks. The tire manufacturing industry accounts for almost 60% of global rubber consumption, with the

butadiene (NBR) and styrene-butadiene (SBR) are tough and/or elastic. SBR is the SBR is the material most commonly used for the production of automobile tires.

Petrochemicals Manufacturing. 373 • Optimize the frequency of tank and equipment cleaning. • Prevent solids and oily wastes from entering the drainage system.

Styrene Butadiene Latex Market Size Industry Share

s-SBR Eni

NMR study of styrene-butadiene rubber (SBR) and TiO2

Butadiene production process overview Chemico-Biological

STYRENE C H kpatents.com

Styrene-butadiene rubber valveproducts.metso.com

Petrochemicals Manufacturing IFC

– US4239863A Process for the polymerization of

Butadiene Manufacture Technology Free Library

1 of 63 KLM Technology Rev 01 Kolmetz.com

Solution Styrene-Butadiene Rubber IHS Markit Home Page

Production Process Overview Introduction Production Process Overview –Emulsion Polymerization of SBR –Solution Polymerization of SBR and PBR Production Economics Emulsion SBR & Solution Polymerization of SBR and PBR Production Economics Tables World Trade Introduction Butyl Rubber Trade Grids Nitrile Rubber Trade Grids Polybutadiene Rubber Trade Grids Emulsion Styrene Butadiene Rubber

5. PRODUCTION IMPORT/EXPORT USE AND DISPOSAL

Solution Styrene Butadiene Rubber (S-SBR) Market Size

Solution polymerized styrene-butadiene rubber is the unrivalled raw material for highly specified tyre components used in the fabrication of high performance tyres, where the lowest fuel consumption and the highest durability are required.

US4239863A Process for the polymerization of

Global Styrene Butadiene Rubber (SBR) Market 2015-2019

As styrene butadiene rubber is one of the key components of synthetic rubber, trends in production and supply of styrene butadiene rubber. Considering the large amount of SBR that is being consumed in the manufacture of tires and tire products, demand is very much dependent on the automotive industry and tire sectors as a whole. As styrene butadiene rubber products are used in almost all

s-SBR Eni

Styrene Butadiene Latex Market Size Industry Share

The industrial production of two styrene−butadiene rubber (SBR) grades is optimized by means of a representative mathematical model. The emulsion process involves a train of seven continuously stirred-tank reactors.

US3350371A Process for the production of styrene

RUBBER PROCESSING TECHNOLOGY tires

The next step is obvious: just add more styrene monomer, and get a styrene-butadiene-styrene triblock copolymer. Easy as pie. Funny thing, though. Although butadiene monomer will add to the anion at the end of a polystyrene chain, styrene monomer won’t add to the anion at the end of a living polybutadiene chain. This is most inconvenient. To get around this, we do a little trick: we’re going

STYRENE C H kpatents.com

Global Styrene Butadiene Rubber (SBR) Market 2015-2019

production of styrene/butadiene rubber (SBR) sati sfied this requirement. Today, millions of Today, millions of tons of synthetic latexes are produced by th e emulsion polymerization process for use in

1 of 63 KLM Technology Rev 01 Kolmetz.com

Solution Styrene-Butadiene Rubber IHS Markit Home Page

Styrene Butadiene Polymer Organic Chemistry Organic

Styrene, butadiene, and carboxylic acid are the primary monomers, and surfactant and other additives including an initiator are charged to create the desirable molecular weight, particle size and gel content.

RUBBER PROCESSING TECHNOLOGY tires

Butadiene Dow Chemical Company

Major uses of 1,3-butadiene include the manufacture of styrene-butadiene rubber, polybutadiene rubber, and adiponitrile. Full text Get a printable copy (PDF file) of the complete article (320K), or click on a page image below to browse page by page.

Petrochemicals Manufacturing IFC

Styrene–butadiene rubber (SBR) production by emulsion

butadiene-styrene (ABS), both representing approximately 9% of styrene use, and styrene-butadiene rubber (SBR), representing approximately 6% of styrene use. SBR is …

STYRENE C H kpatents.com

Petrochemicals Manufacturing IFC

Styrene, the simplest and most important member of a series of aromatic monomers, is produced in large quantities for polymerization. Its versatility has resulted in the manufacture of plastics, including polystyrene, ABS, SAN, styrene–butadiene latex, SBR, and unsaturated polyester resins. Polystyrene accounts for 65% of total styrene demand. Rapid growth in styrene production has been seen

Continuous Emulsion Styrene−Butadiene Rubber (SBR) Process

Solution Styrene-Butadiene Rubber IHS Markit Home Page

THE USE OF STYRENE-BUTADIENE RUBBER WASTE AS A SciELO

Evaluation the Effects of Styrene Butadiene Rubber Addition as a New Soil Stabilizer on Geotechnical Properties.pdf Kirk-Othmer Encyclopedia of Chemical Technology V5 4th Edition.pdf Influence of Silane Coupling Agent on Pyrolysis Pattern Of

RUBBER PROCESSING TECHNOLOGY tires

Rubber Compounds soynewuses.org

Rubber Processing and Profiting Compounding, Mixing, Vulcanization, Extrusion, Materials, Principles Rubber Products, Natural Rubber Processing, Rubber Reclaiming. http://www.entrepreneurindia.co The production of rubber and rubber products is a large and diverse industry. The rubber product manufacturing industry is basically divided into two major sectors: tyre and non-tyre. The tyre sector

(PDF) Mortality of a Cohort of Workers in the Styrene

Emulsion Styrene-Butadiene Rubber from Brazil Korea

The chemical behavior of styrene-butadiene rubber (SBR) and of the SBR/TiO2 and photodegraded SBR/TiO2 nanocomposites was investigated through nuclear …

NMR study of styrene-butadiene rubber (SBR) and TiO2

4.12 Manufacture of Rubber Products. 4.12.1 General Process Description1. Many of the rubber manufacturing facilities in the United States produce pneumatic tires for automobile, trucks, airplanes and farm machinery. However, many rubber manufacturing facilities produce other engineered rubber products. The processes involved in these industries are very similar. Differences basically consist

Styrene Butadiene Polymer Organic Chemistry Organic

Solution Styrene Butadiene Rubber (S-SBR) Market Size

The industrial production of two styrene−butadiene rubber (SBR) grades is optimized by means of a representative mathematical model. The emulsion process involves a train of seven continuously stirred-tank reactors.

Global Styrene-butadiene rubber (SBR) Market 2018 Trends

exothermic process, the reaction can become self accelerating. Styrene homo polymerization can occur either by free-radical or ionic reactions. The resultant polymer, polystyrene, is a clear, crystalline-type compound.6-s ABS polymers (Fig. 2) can be produced by two general methods, each of which generates a different type of plastic. Type A ABS polymers are produced by a mechan ical

Butadiene Manufacture Technology Free Library

Styrene Kirk-Othmer Encyclopedia of Chemical Technology

STYRENE BUTADIENE ELASTOMER Markit

The XSBR latexes (styrene-butadiene carboxylated latexes, also known as “CBX”) process is based on an emulsion polymerization reaction in a semibatch (“seed polymerization”) reactors.

Polymer SBR Rubber Technology

Solution Styrene Butadiene Rubber (S-SBR) Market Report

Styrene Kirk-Othmer Encyclopedia of Chemical Technology

Abstract – Styrene-butadiene rubber (SBR) has large applications in the shoe industry, especially as expanded sheets used to produce insoles and inner soles. According to TG analysis, the rubber …

Styrene-Butadiene Rubber Production By Intratec Solutions

Global Styrene Butadiene Rubber (SBR) Market 2015-2019

Abstract – Styrene-butadiene rubber (SBR) has large applications in the shoe industry, especially as expanded sheets used to produce insoles and inner soles. According to TG analysis, the rubber …

Emulsion Styrene-Butadiene Rubber from Brazil Korea

Global Styrene Butadiene Rubber (SBR) Market 2015-2019

sbr (styrene-butadiene-rubber) tyrene-butadiene rubbers (SBR) are copolymers used two monomer styrene and butadiene. utadiene structural units can be as cis-1.4, trans-1.4 or 1.2 (vinyl) units.

US4239863A Process for the polymerization of

Styrene Kirk-Othmer Encyclopedia of Chemical Technology

(PDF) Mortality of a Cohort of Workers in the Styrene

Industry Insights. In 2016, the global solution styrene butadiene rubber (S-SBR) market size was valued at USD 2.51 billion. The demand for S-SBR in footwear and tire applications is increasing owing to its high synthetic flexibility is expected to drive market growth.

Making SBS Rubber pslc

Polybutadiene Properties Applications Processing and

Styrene, the simplest and most important member of a series of aromatic monomers, is produced in large quantities for polymerization. Its versatility has resulted in the manufacture of plastics, including polystyrene, ABS, SAN, styrene–butadiene latex, SBR, and unsaturated polyester resins. Polystyrene accounts for 65% of total styrene demand. Rapid growth in styrene production has been seen

RUBBER PROCESSING TECHNOLOGY tires

Production of styrene–butadiene rubber and polybutadiene rubber accounts for about 54% of global butadiene demand, with tire production being the single most important end use of butadiene synthetic rubbers. Other major butadiene derivatives are acrylonitrile–butadiene–styrene (ABS) and styrene butadiene latex (about 24% of demand combined).

Styrene Butadiene Latex Market Size Industry Share

Styrene Butadiene Rubber Market Growth Analysis By 2025

Styrene-butadiene rubber is currently the largest volume synthetic rubber, which is produced by the copolymerization of styrene and butadiene by either the emulsion or solution process. Although the emulsion process is clearly the current capacity leader, the solution process has better future potential due to versatility and flexibility in imparting desired polymer structure. The current

Solution Styrene Butadiene Rubber (S-SBR) Market Size

Petrochemicals Manufacturing IFC

RUBBER PROCESSING TECHNOLOGY 1. Rubber Processing and Shaping 2. Manufacture of Tire and other Rubber Products 3. Design Consideration 2 Introduction • Similar to the processing of plastics • But the rubber industry is quite different from the plastics industry • Dominated by one product: tires • Technological breakthrough – Vulcanization (cross-linking) to transform weak natural

Styrene-Butadiene Rubber Production By Intratec Solutions

copolymerization of styrene and butadiene. Polybutadiene is formed from the polymerization process of 1,3-butadiene Polybutadiene is formed from the polymerization process of 1,3-butadiene monomer.

The industrial production and use of 13-butadiene.

THE USE OF STYRENE-BUTADIENE RUBBER WASTE AS A SciELO

NMR study of styrene-butadiene rubber (SBR) and TiO2

The next step is obvious: just add more styrene monomer, and get a styrene-butadiene-styrene triblock copolymer. Easy as pie. Funny thing, though. Although butadiene monomer will add to the anion at the end of a polystyrene chain, styrene monomer won’t add to the anion at the end of a living polybutadiene chain. This is most inconvenient. To get around this, we do a little trick: we’re going

Styrene Butadiene Rubber Market Growth Analysis By 2025

Continuous Emulsion Styrene−Butadiene Rubber (SBR) Process

Butadiene Dow Chemical Company

Typical monomers used for production feed material include butadiene, styrene, isoprene, chloroprene, acrylonitrile, ethylene or propylene. These monomers are then polymerized using catalyst and process steam to form chains of polymers which results in rubber intermediaries. These substances are then processed to their final rubber products by vulcanization. In integrated plants, naphtha or

Styrene Butadiene Polymer Organic Chemistry Organic

s-SBR Eni

The process The following paragraphs describe a cold emulsion-polymerization process for SBR production from butadiene and styrene. SBR grades generated in this type of process are usually referred to as emulsion SBR (eSBR). Figure 1 presents a simplified flow diagram of the process, showing the main pieces of equipment. Figure 1. This figure shows a diagram of SBR production from styrene …

US4239863A Process for the polymerization of

US3350371A Process for the production of styrene

Polymer SBR Rubber Technology

styrene-butadiene rubber (SBR), polybutadiene rubber (PBR), polychloroprene (Neoprene) and nitrile rubber (NR). However, the major use of butadiene is in the production of tires. Butadiene is consumed in the manufacture of polymers, latexes, and plastics. Rubbers and latexes made from butadiene are used to make the following goods and materials: SBR and PBR are used to produce …

Solution Styrene Butadiene Rubber (S-SBR) Market Report

Butadiene Manufacture Technology Free Library

Butadiene production process overview ScienceDirect

Styrene-Butadiene Rubber by Solution Process Production Costs at Difference Production Levels . . Styrene-Butadiene Rubber by Alfin Process Using High

Global Styrene Butadiene Rubber (SBR) Market 2015-2019

STYRENE BUTADIENE ELASTOMER Markit

1. Introduction. Styrene–butadiene rubber (SBR) is a synthetic elastomer with wide range of industrial applications. Due to its excellent abrasion resistance and stability it is extensively used as a …

(PDF) Mortality of a Cohort of Workers in the Styrene

US3350371A Process for the production of styrene

STYRENE-BUTADIENE RUBBER LATEX POLYMERS WITH PSTC

Production of styrene–butadiene rubber and polybutadiene rubber accounts for about 54% of global butadiene demand, with tire production being the single most important end use of butadiene synthetic rubbers. Other major butadiene derivatives are acrylonitrile–butadiene–styrene (ABS) and styrene butadiene latex (about 24% of demand combined).

US3350371A Process for the production of styrene

Rubber Synthesis Processing KSU Faculty

Major uses of 1,3-butadiene include the manufacture of styrene-butadiene rubber, polybutadiene rubber, and adiponitrile. Full text Get a printable copy (PDF file) of the complete article (320K), or click on a page image below to browse page by page.

Polybutadiene Properties Applications Processing and

(PDF) Mortality of a Cohort of Workers in the Styrene

Styrene-butadiene rubber valveproducts.metso.com

Styrene-butadiene rubber is currently the largest volume synthetic rubber, which is produced by the copolymerization of styrene and butadiene by either the emulsion or solution process. Although the emulsion process is clearly the current capacity leader, the solution process has better future potential due to versatility and flexibility in imparting desired polymer structure. The current

s-SBR Eni

styrene-butadiene rubber (SBR), polybutadiene rubber (PBR), polychloroprene (Neoprene) and nitrile rubber (NR). However, the major use of butadiene is in the production of tires. Butadiene is consumed in the manufacture of polymers, latexes, and plastics. Rubbers and latexes made from butadiene are used to make the following goods and materials: SBR and PBR are used to produce …

Solution Styrene Butadiene Rubber (S-SBR) Market Report

US4239863A Process for the polymerization of

The rubber market is categorized as natural rubber (NR), which is obtained from rubber trees, and synthetic rubber, which is manufactured with petroleum-based feedstocks. The tire manufacturing industry accounts for almost 60% of global rubber consumption, with the

Styrene Butadiene Latex Market Size Industry Share

US3350371A Process for the production of styrene

Difference Between Styrene and Polystyrene Styrene vs

About SBR. SBR is a synthetic rubber formed by the copolymerization of styrene and butadiene in the ratio of 3:1 by weight. SBR is manufactured through two different processes: emulsion and solution, to form emulsion-SBR and solution-SBR, respectively.

US4239863A Process for the polymerization of